5-Axis Machining: Key Differences and Advantages Over 3-Axis & 4-Axis

Manufacturing technology has evolved dramatically to meet the changing demands of various industries. Machining, a core manufacturing technology, creates high-precision parts by removing material from a solid block. While this was traditionally done using relatively simple 3-axis tools, the process has been revolutionized by Computer Numerical Control (CNC), particularly 5-axis machining. But what distinguishes these technologies? This article breaks down the key differences between 3-axis, 4-axis, and 5-axis CNC machining to help you select the optimal process for your components.

Understanding the Axes: The Foundation of CNC Machining

Milling is a critical precision machining technology used across aerospace, medical, optical, and mechanical industries. It uses a rotating cutting tool to remove material from a workpiece. The number of axes a machine has dictates the type of part it can produce and the complexity of operations it can perform.

- X-axis: Left to right movement

- Y-axis: Front to back movement

- Z-axis: Up and down movement

- A-axis: Rotation around the X-axis

- B-axis: Rotation around the Y-axis

- C-axis: Rotation around the Z-axis

3-Axis Machining: The Workhorse

3-axis machining is one of the most widely used technologies for manufacturing mechanical parts. It operates along the three linear axes (X, Y, and Z). The cutting tool moves in these three directions to mill the material, while the workpiece remains stationary.

- Advantages: Simple, cost-effective, excellent for prismatic parts with 2.5D geometries, automated drilling, and sharp edge cutting.

- Limitations: Struggles with deep, narrow cavities and complex contours. Achieving a perfect surface finish on complex curves can be challenging and time-consuming. Each side of a part requires a separate setup, increasing fixturing time and potential for error.

4-Axis Machining: Adding Rotation

A 4-axis CNC machine operates on the X, Y, and Z axes but adds a rotational axis, typically the A-axis (rotation around X). This allows the workpiece to rotate, enabling machining on multiple sides without manual repositioning.

- Advantages: Ideal for machining cylindrical parts, engraving on curved surfaces, and cutting holes or features on the sides of a workpiece. Significantly reduces setup time for parts requiring features on multiple planes compared to 3-axis.

- Common Use Cases: Automotive camshafts, structural aerospace components, and custom fittings.

5-Axis Machining: The Pinnacle of Flexibility

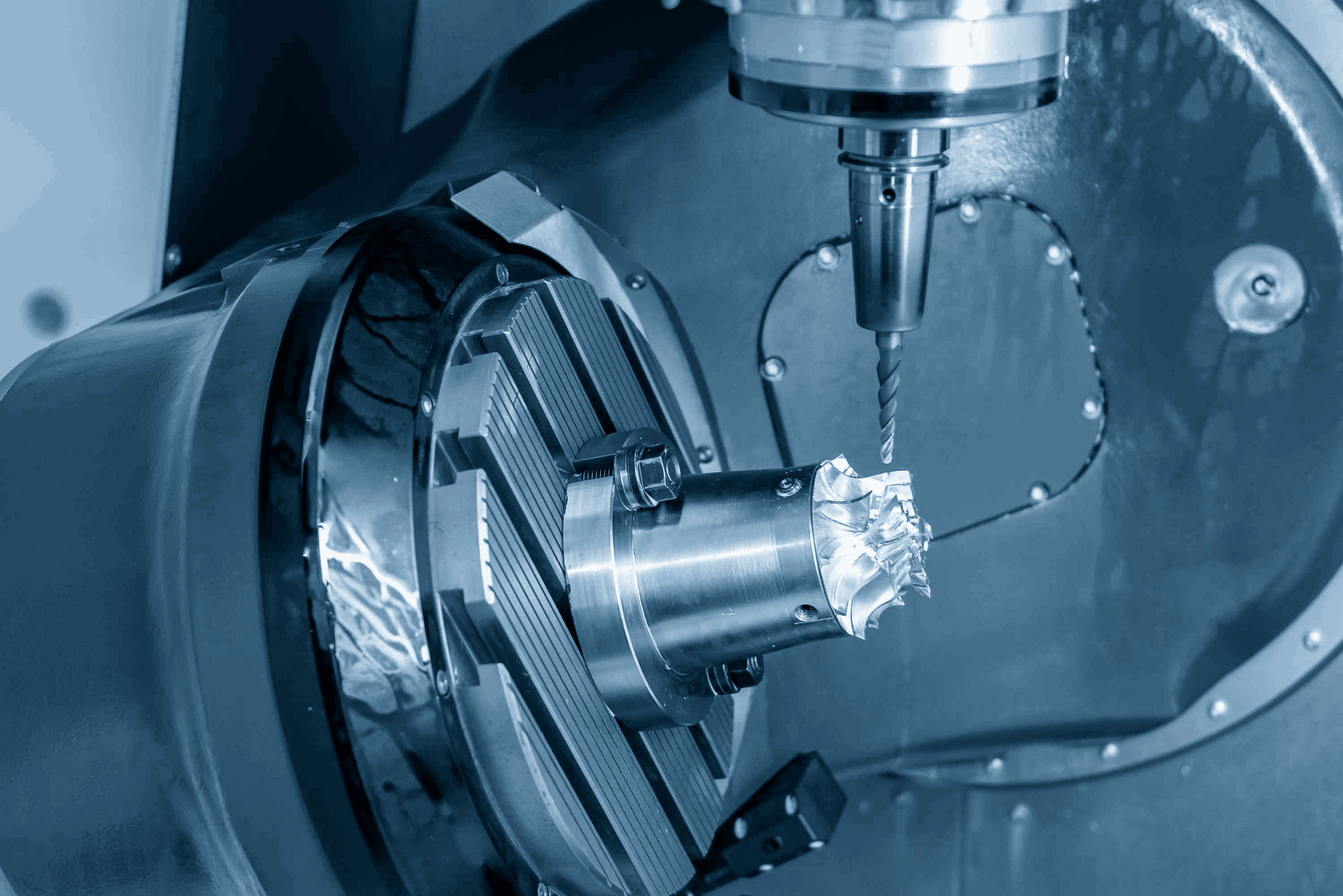

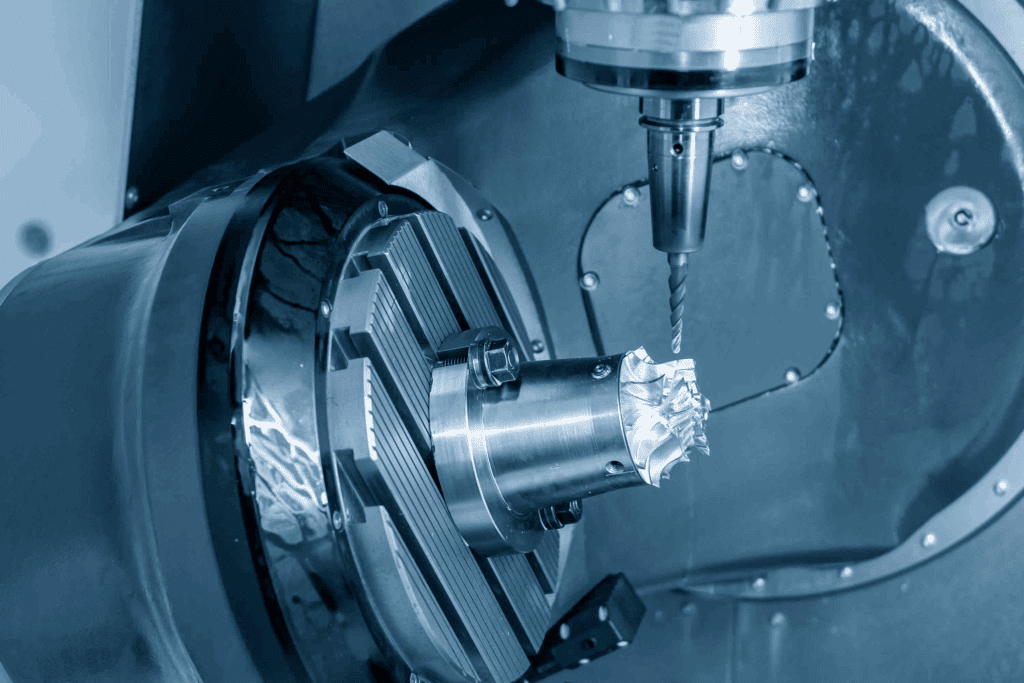

5-axis machining is the most advanced subtractive manufacturing technology. The tool moves along the three linear axes (X, Y, Z) while simultaneously rotating on two additional rotary axes (typically A and B). This allows the cutting tool to approach the workpiece from any direction in a single setup.

There are two main configurations:

- Table/Table: The two rotary axes are on the table that holds the workpiece.

- Head/Head: The rotary axes are on the head that holds the tool.

- Table/Head: A hybrid with one rotary on the table and one on the head.

Key Advantages of 5-Axis Machining:

- Single Setup Efficiency: Machine complex parts on five sides in one clamping. This eliminates errors from multiple setups, drastically reduces lead times, and minimizes fixture costs.

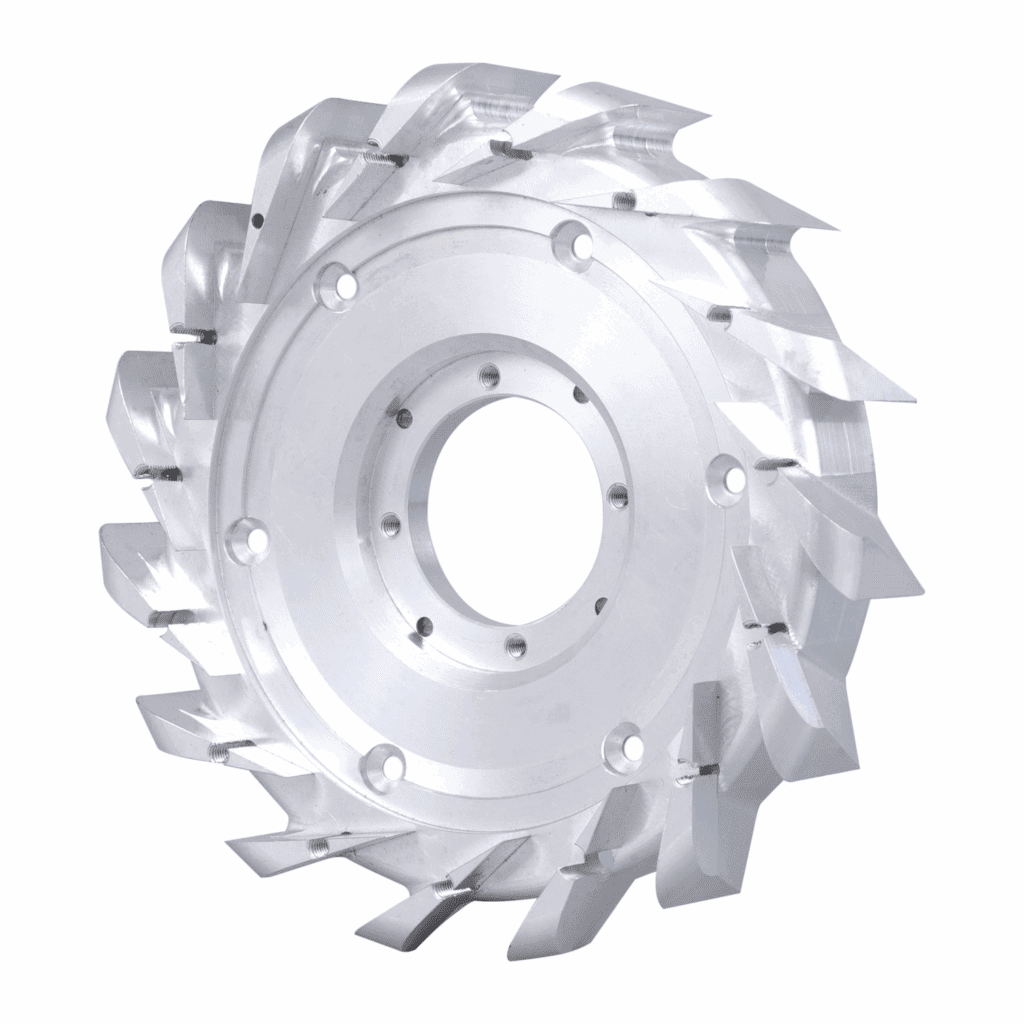

- Superior Access to Complex Geometry: Unmatched capability for machining intricate contours, deep cavities, undercuts, and organic shapes common in aerospace, medical implants, and turbomachinery components.

- Enhanced Precision & Surface Finish: By tilting the tool, the machine can use shorter, more rigid cutters, reducing tool vibration (chatter). This allows for higher feed rates and delivers exceptional surface quality, often eliminating the need for hand finishing.

- Improved Tool Life & Performance: Tilting the tool maintains the most efficient cutting position and optimal chip load. This extends tool life and enables faster material removal rates (MRR), especially when machining tough materials like titanium or Inconel.

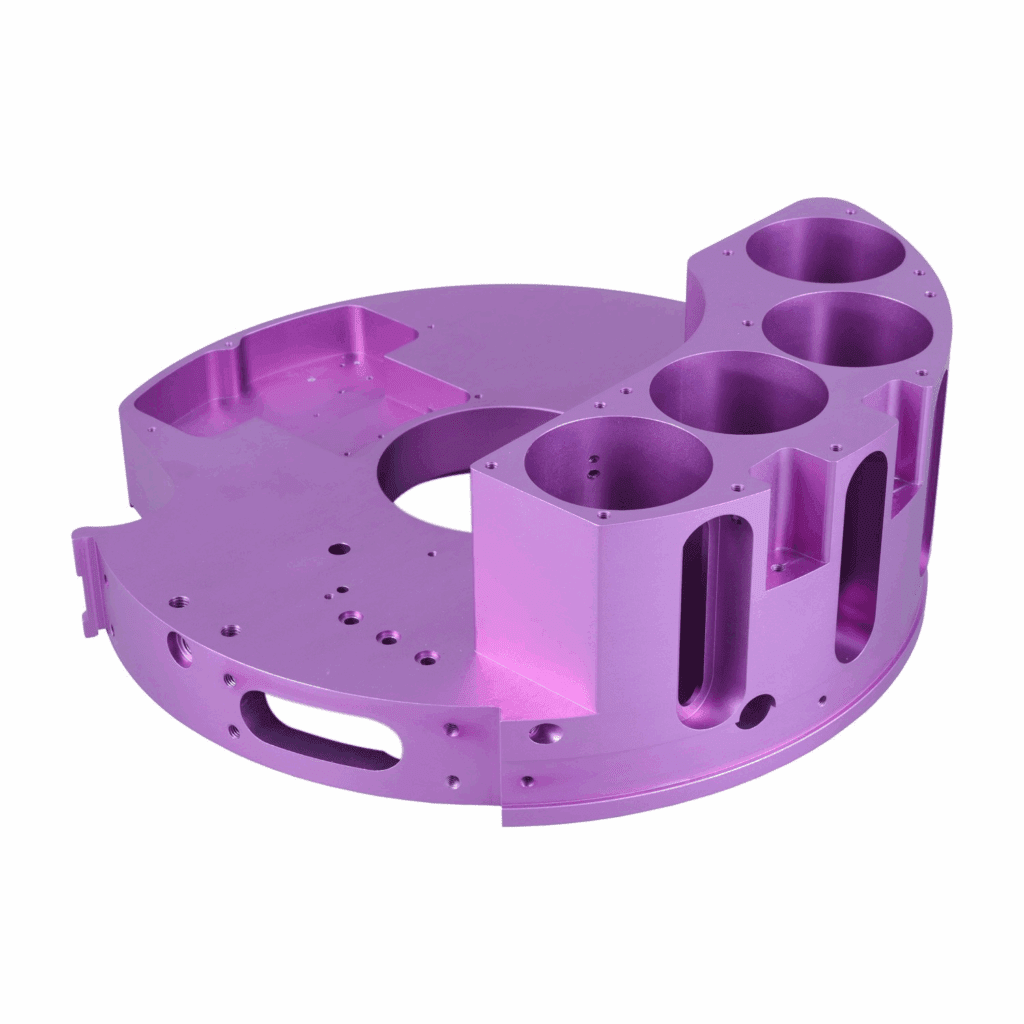

- 3+2 Axis Machining (Positional 5-Axis): A powerful subset where the two rotary axes position the workpiece, and then machining occurs with the three linear axes. This is perfect for machining multiple sides of a box-like part in one setup without the complexity of full simultaneous 5-axis toolpaths.

Why Choose 5-Axis Machining?

While 5-axis excels at ultra-complex parts, its biggest value often lies in simplifying the production of moderately complex parts. It is not just for aerospace; it’s increasingly used for molds, dies, architectural elements, and high-value prototypes.

The benefits are clear:

- Reduced Lead Time: Consolidate multiple operations into one setup.

- Higher Accuracy: Eliminate cumulative errors from repeated part repositioning.

- Complex Part Production: Create geometries that are impossible with 3-axis or 4-axis.

- Cost-Effectiveness for Complex Jobs: While the hourly machine rate is higher, the total cost per part for complex components is often lower due to reduced labor, fixturing, and secondary processing.

Applications of Advanced CNC Technology

The evolution of multi-axis machining underpins modern manufacturing across sectors:

- Aerospace: Impellers, turbine blades, structural components.

- Medical: Prosthetics, orthopedic implants, surgical instruments.

- Automotive: Cylinder heads, prototypes, complex molds.

- Energy: Turbine components, heat exchangers.

- Optics: Precision lenses and mirror mounts.

This technology is supported by advanced CAM (Computer-Aided Manufacturing) software, which is crucial for programming efficient, collision-free toolpaths for 5-axis machines.

Partner with a Precision Machining Expert

Choosing the right technology—3-axis, 4-axis, or 5-axis—is critical to the success of your project. It depends on your part’s geometry, material, required precision, volume, and budget.

At [Your Company Name], we leverage a full spectrum of advanced manufacturing technologies. Our expertise allows us to select the most efficient process, whether it’s 3-axis, 4-axis, or 5-axis CNC machining, to deliver truly custom, high-precision results in various metals and plastics. We provide comprehensive support from DFM (Design for Manufacturability) advice to final inspection.

Ready to optimize your manufacturing process? Contact our team of precision engineers today for an expert consultation and quote.