CNC Machining Applications: Industries, Parts & Processes Explained

(Introduction)

CNC (Computer Numerical Control) machining stands as a cornerstone of modern manufacturing, offering unparalleled precision, repeatability, and versatility. From prototyping to high-volume production, its applications span virtually every industry that requires high-quality, complex parts. As a leader in precision CNC machining services, we break down the key industries we serve, the critical components we produce, and the specific machining processes that deliver optimal results for our global B2B partners.

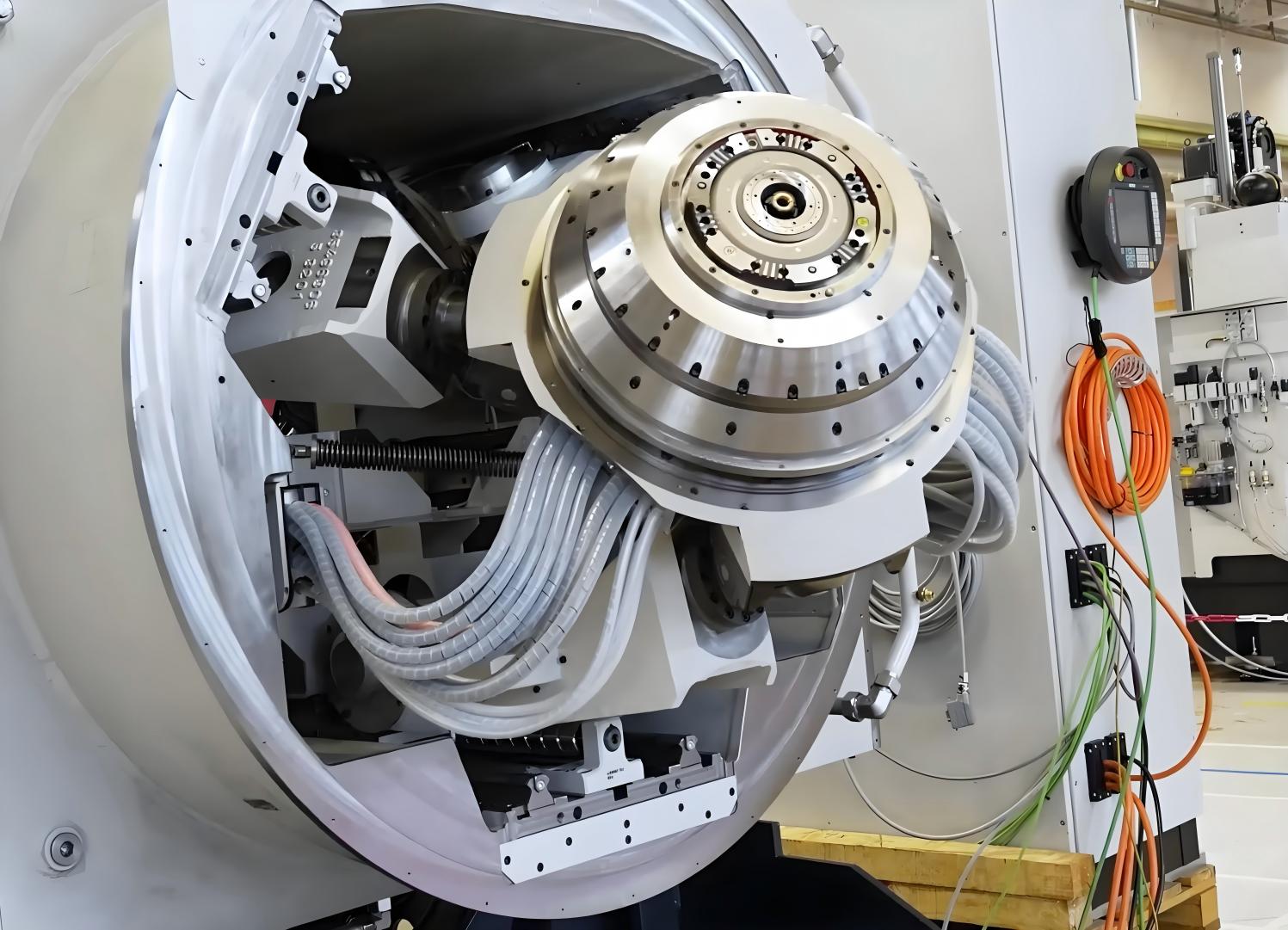

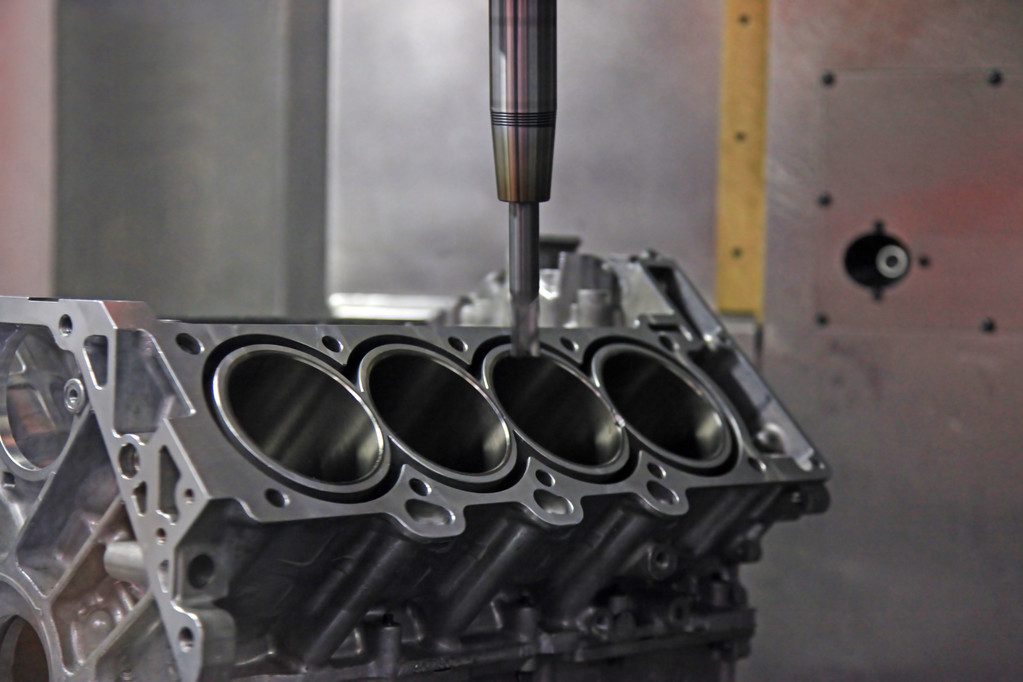

1. Aerospace & Defense Industry

The aerospace sector demands the absolute highest standards of quality, precision, and material performance. Components must withstand extreme stresses, temperatures, and adhere to stringent certifications like AS9100.

- Key Applications: Structural components, engine mounts, landing gear parts, hydraulic manifolds, drone components, and communication satellite parts.

- Common Materials: Aluminum alloys (e.g., 7075, 6061), Titanium (e.g., Grade 5, Ti6Al4V), High-strength stainless steels, and advanced composites.

- Primary CNC Processes: 5-Axis Milling is indispensable for creating complex, aerodynamic geometries from solid blocks of metal. Precision CNC Turning is used for producing shafts, couplings, and fasteners. Swiss-style Machining is ideal for producing long, slender, and highly precise components.

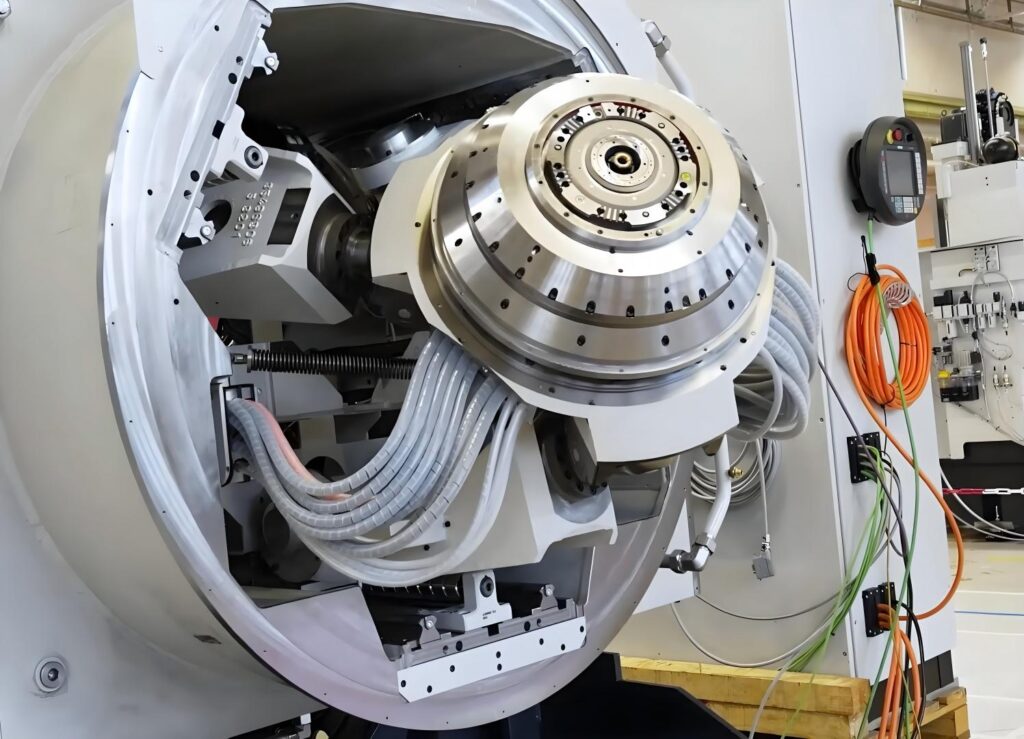

2. Automotive & Transportation Industry

The automotive industry leverages CNC machining for both rapid prototyping of new designs and manufacturing durable, reliable parts for mass production, including electric vehicles (EVs).

- Key Applications: Engine blocks, cylinder heads, transmission cases, suspension components, brake system parts, custom jigs and fixtures, and EV battery enclosures.

- Common Materials: Aluminum, cast iron, brass, and various engineered plastics like PEEK and Nylon.

- Primary CNC Processes: Multi-Axis Milling and CNC Turning are workhorses for engine and drivetrain components. CNC Drilling and Tapping are crucial for creating precise hole patterns.

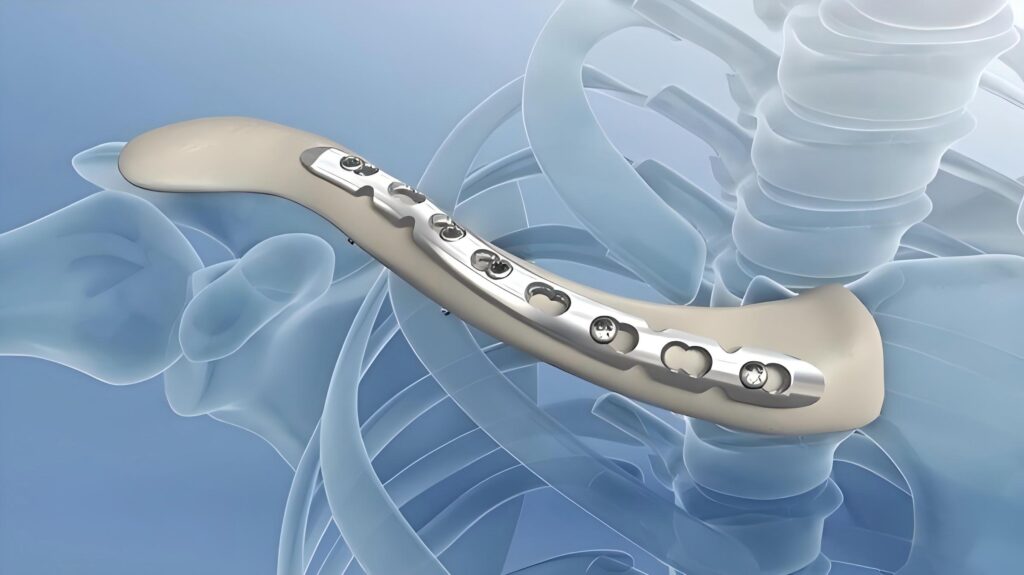

3. Medical & Surgical Industry

Medical device manufacturing requires biocompatible materials, micromachining capabilities, and extreme precision to meet critical FDA and ISO 13485 standards.

- Key Applications: Surgical instruments (forceps, scalpels), implants (knee, hip, spinal), MRI machine components, dental drills, and housings for medical devices.

- Common Materials: Medical-grade stainless steel (e.g., 316L), Titanium, Cobalt-Chrome alloys, and medical plastics.

- Primary CNC Processes: Micro-Machining and Swiss CNC Machining produce tiny, intricate parts with tight tolerances. 5-Axis Milling creates complex, patient-specific implants. Processes often require validated, sterile environments.

4. Electronics & Consumer Goods Industry

This fast-paced industry relies on CNC machining for creating durable prototypes, custom enclosures, and heat management solutions with excellent aesthetic finishes.

- Key Applications: Semiconductor fixtures, heat sinks, device housings, connectors, and molds for plastic injection molding.

- Common Materials: Aluminum (for its great strength-to-weight ratio and thermal conductivity), brass, copper, and engineering plastics like ABS and Polycarbonate.

- Primary CNC Processes: 3-Axis Milling is perfect for creating boxes, panels, and brackets. CNC Turning produces connectors and pins. A emphasis is placed on surface finishing (e.g., anodizing, powder coating) for aesthetic and protective purposes.

5. Oil & Gas Industry

Equipment for oil and gas exploration and processing must be incredibly robust, resistant to corrosion, and reliable under high-pressure environments.

- Key Applications: Valve bodies, pistons, drill bits, pump components, and manifolds for downstream processing.

- Common Materials: High-strength, corrosion-resistant alloys like Inconel, Duplex Stainless Steel, and Hastelloy.

- Primary CNC Processes: Heavy-Duty CNC Milling and Turning are used to machine these often large and tough materials. The ability to maintain integrity in complex part geometries is critical.

Why Partner with a Expert CNC Machining Supplier?

Choosing the right manufacturing partner is crucial. Look for a supplier with:

- Broad Capabilities: Mastery of milling, turning, and multi-axis machining.

- Material Expertise: Knowledge of machining a wide range of metals and plastics.

- Stringent Quality Control: In-process inspection and final verification with CMMs and other metrology tools.

- Certifications: Compliance with international standards like ISO 9001.

- Global Supply Chain Experience: Proven expertise in managing logistics and delivering to clients worldwide efficiently.

(Conclusion)

CNC machining’s adaptability makes it a vital technology driving innovation across global industries. Whether you are in aerospace, medical, or any field in between, understanding the right processes and materials for your application is key to success.

Ready to Precision-Machine Your Components?

[Your Company Name] is a trusted ISO-certified CNC machining partner for B2B clients worldwide. We combine state-of-the-art technology with deep engineering expertise to deliver high-quality, custom parts on time and to specification.

Contact us today for a free quote and design for manufacturability (DFM) analysis.