CNC Machining vs. 3D Printing: Which Technology Wins for Your Project?

In the world of modern manufacturing, two powerful technologies dominate the landscape: CNC Machining and 3D Printing. For engineers, designers, and procurement managers, choosing between them is a critical decision that impacts cost, lead time, and part quality. The most fundamental difference is this: CNC machining is a subtractive manufacturing process, while 3D printing is an additive manufacturing process. This core distinction influences everything from material options to final part properties.

1. Material Differences: Versatility vs. Specialization

3D Printing (Additive Manufacturing):

3D printing utilizes layer-based additive technologies that build parts from specialized materials. The most common industrial materials include:

- Photopolymer Resins (SLA/DLP): For high-detail prototypes and visual models.

- Nylon Powders (SLS): For durable, functional prototypes with complex geometries and good mechanical properties.

- Metal Powders (SLM/DMLS): For direct metal parts used in aerospace, medical, and automotive industries.

- Thermoplastic Filaments (FDM): For low-cost prototyping and conceptual models.

While offering a range of specialized materials, the selection is inherently limited to what can be used in additive processes. Finished part density and isotropic strength can be challenges, especially with some polymer powders.

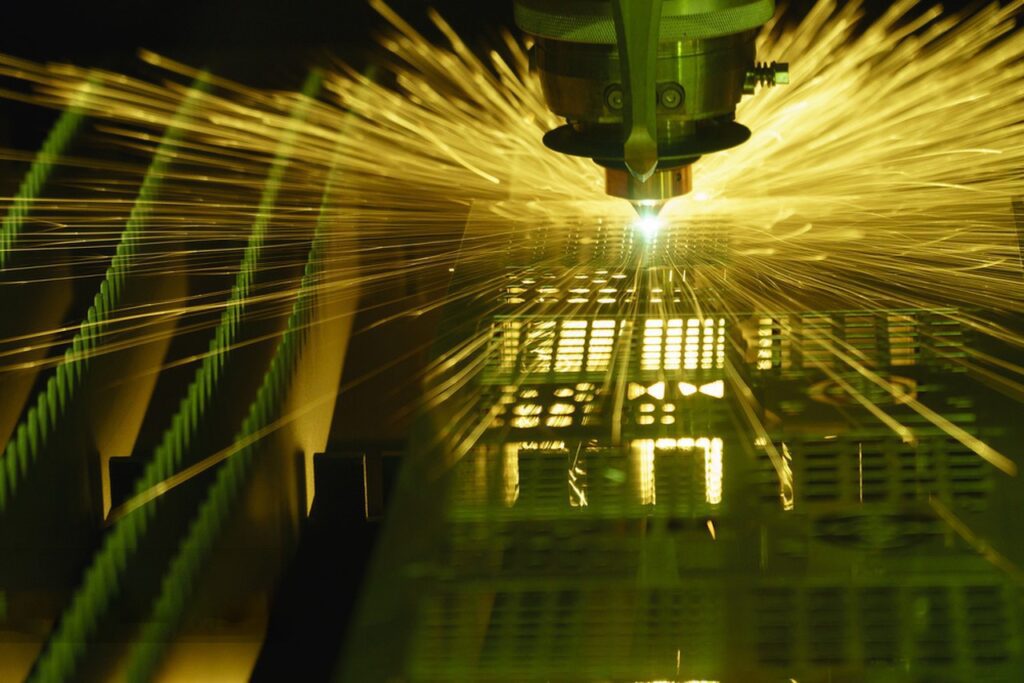

CNC Machining (Subtractive Manufacturing):

CNC machining starts with a solid block of material (a billet or sheet) and removes material to achieve the desired shape. This provides a significant advantage in material selection:

- Metals: Aluminum, stainless steel, titanium, brass, copper, and exotic alloys.

- Plastics: ABS, Nylon, Polycarbonate, PEEK, PTFE, and many more.

- Composites: Delrin, G-10, and Phenolics.

The key advantage is that CNC parts are made from industry-standard, dense, and homogeneous materials. This results in superior mechanical properties, better fatigue strength, and higher temperature resistance compared to most 3D printed parts. The material’s integrity is proven and predictable.

2. Part Geometry: Complexity vs. Precision

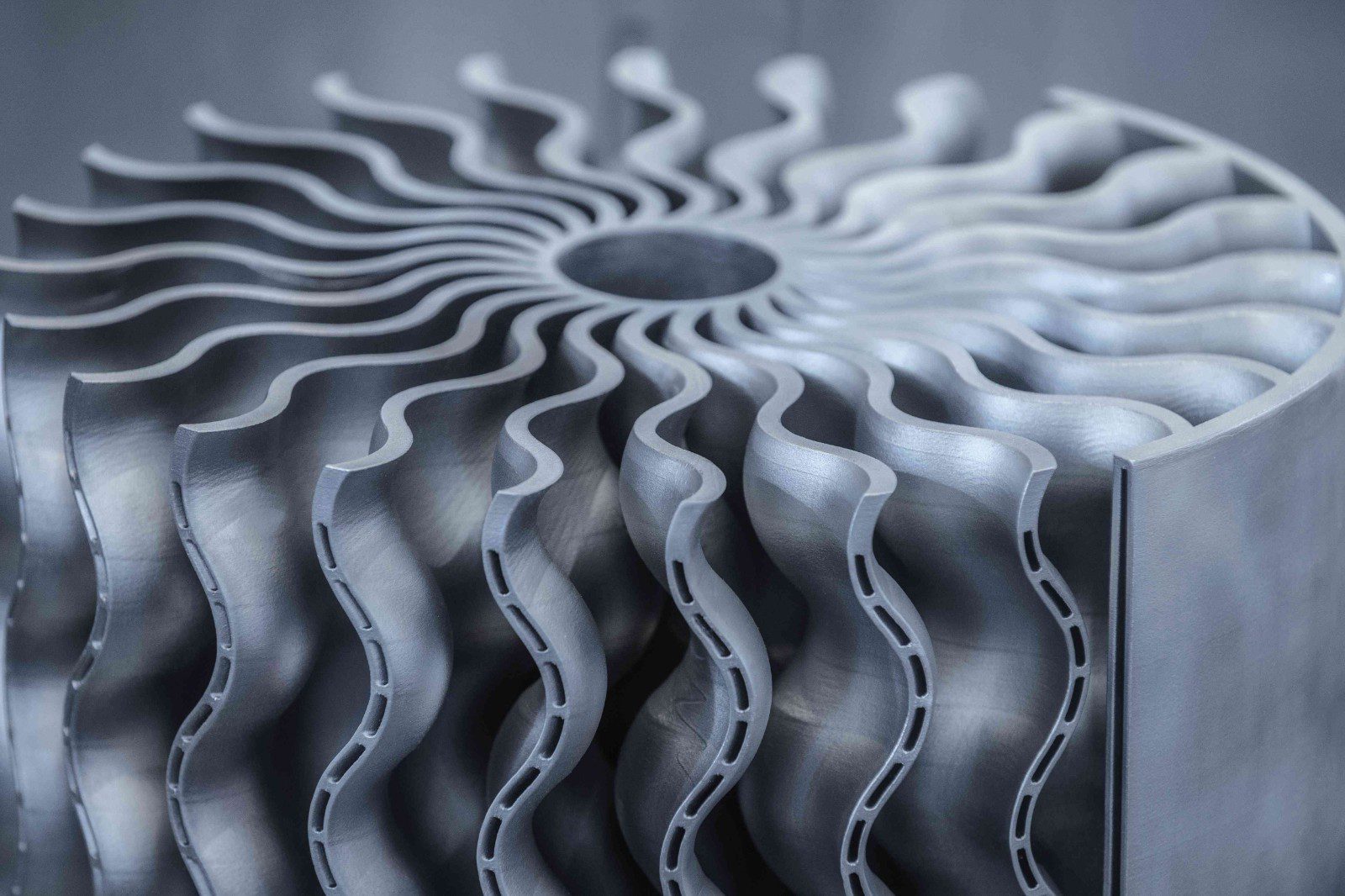

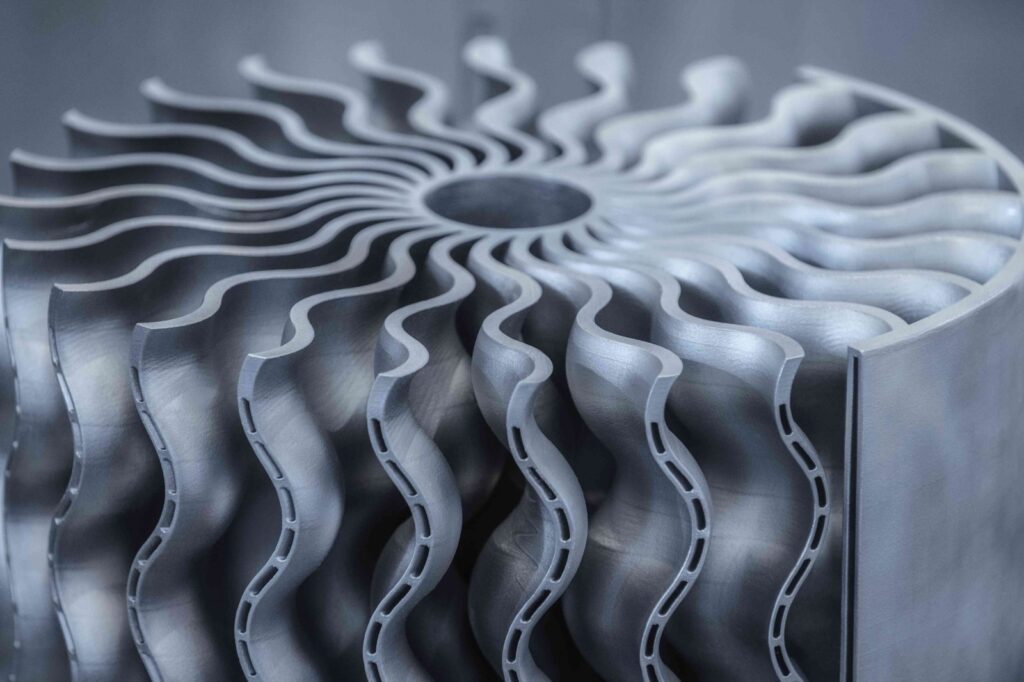

3D Printing: Champion of Complexity

Additive manufacturing excels at producing parts with intricate, complex internal structures that would be impossible or prohibitively expensive to create subtractively. It is the ideal choice for:

- Organic Shapes & Lattices: Lightweighting components with complex internal lattices.

- Undercuts & Hollow Parts: Creating hollow, enclosed structures without assembly.

- Single-Piece Assemblies: Consolidating multiple assembled components into one printed part.

However, it struggles with fine feature resolution and surface finish on vertical curves, often requiring significant post-processing.

CNC Machining: Master of Precision & Finish

CNC machining, through multi-axis milling (3-axis, 5-axis) and turning, is unparalleled for achieving tight tolerances (often within ±0.025mm or better) and excellent surface finishes. Its limitations and strengths include:

- Geometric Constraints: It cannot machine true internal 90-degree corners without specialized tooling; these require EDM (Electrical Discharge Machining) or other secondary processes. Internal radii are inevitable.

- Surface Quality: While machining complex curved surfaces is possible with 5-axis CNC, it is time-consuming and requires expert CAM programming to avoid visible tool marks. 3D printing can often produce complex curves more efficiently.

- Analogy: A helpful analogy is that 3D printing builds a cake layer-by-layer, while CNC machining precisely carves the final part from a solid block.

3. Software & Operational Expertise

3D Printing: Accessible and Automated

3D printing software (slicers) has been designed for accessibility. The process of preparing a model (slicing) is highly automated, with software automatically generating support structures. This low barrier to entry has driven its adoption from professional workshops to home users.

CNC Machining: Expert-Driven and Complex

CNC machining requires advanced expertise. The process involves:

- CAD/CAM Software: Using complex software like UG (NX), Mastercam, PowerMill, or Fusion 360 to create a toolpath strategy. This requires knowledge of tool selection, feed rates, spindle speeds, and chip load.

- Skilled Programmers & Operators: A zero-base individual typically requires months of training to become proficient. A single part can have dozens of viable machining strategies, and the programmer’s experience is crucial for optimizing cycle time, tool wear, and surface finish.

4. Post-Processing and Finishing Options

3D Printing: Limited Options

Post-processing for 3D printed parts is often necessary to improve surface quality but options are more limited. Common methods include support removal, sanding, polishing, priming, painting, and dyeing.

CNC Machining: Unmatched Versatility

CNC machined parts, particularly metal ones, benefit from a vast array of professional finishing techniques:

- Aesthetic: Bead blasting, polishing, anodizing (Type II/III), painting, powder coating.

- Functional: Hard anodizing, chromate conversion coating, passivation, heat treatment, plating (nickel, chrome).

- Marking: Laser engraving, silk screening, pad printing.

This makes CNC the clear choice for parts that require a commercial-grade, durable finish.

Conclusion: How to Choose the Right Technology?

The choice isn’t about which technology is “better,” but which is right for your specific project.

Choose 3D Printing when:

- You need complex, organic geometries or internal lattices.

- Rapid prototyping and design iteration speed are critical.

- Part consolidation is a key goal.

- You are working with budgets that cannot accommodate high tooling costs.

- Production volume is low.

Choose CNC Machining when:

- You require tight tolerances and exceptional mechanical properties.

- You need parts made from standard, engineering-grade metals or plastics.

- Superior surface finish and a wide range of post-processing options are required.

- Production volume is medium to high (offering economies of scale).

- Part geometry is best suited to subtractive methods (e.g., primarily prismatic shapes).

Partner with a Manufacturer Who Offers Both.

The most sophisticated manufacturing partners offer both CNC Machining and 3D Printing services. They can provide expert Design for Manufacturability (DFM) feedback, guiding you to the most cost-effective and suitable technology for your application.

Unsure which technology is optimal for your component? [Contact Our Experts Today] for a free design review and quote. We’ll help you navigate the trade-offs and select the perfect process to ensure your project’s success.